Aries Green Solutions plays a major role in formulating and implementing the specific needs of clients and operational requirements of charterers. Our Project Management team ensures effective coordination of the various stages involved in the project execution. The vessel owner is provided with a hassle- free compliance of the regulations and project specific requirements.

Honed with years of experience, we have developed our capabilities to provide extensive inspection management services to the industry. Our management approach encompasses the entire project management of the inspection process ranging from planning, resource management, work scope preparation, work pack compilation, Site supervision & reporting and data analysis. This makes Aries Green Solutions the preferred Project Managers for Green solutions in the maritime and offshore industries worldwide.

Aries Green Solutions has proven track record of turnkey Ballast Water Management projects around the world.

The services include:

SUPERVISION OF PREFABRICATION

The experienced team reviews supervises the prefabrication of equipment, in order to ensure compliance with the drawings and specifications.

INSTALLATION SUPERVISION

We have fully established project team having the capabilities of handling various installation jobs across the globe. We can provide the installation services of our project team to any part of the work to ensure smooth and efficient running of the project

COMMISIONING SUPPORT

The team of technicians are qualified and trained by the equipment supplier itself. Our technicians are scattered across all major hubs including China, Singapore, Middle East and Azerbaijan. This ensures quality commissioning services.

ARIES GREEN SOLUTIONS SCOPES:

1. BALLAST WATER MANAGEMENT

To combat the problem of invasive species from ballast water, the IMO adopted the International Convention for the Control and Management of Ships’ Ballast Water and Sediments in 2004. On 8 September 2017, the convention entered into force.

To obtain the International BWM Certificate, a vessel must

- Have a BWM Plan addressing procedures for BW exchange, BW treatment or both.

- If a BWM System is installed, then approved technical documentation for the BW treatment system installation must be available on board.

- A Ballast Water record book is required, and the vessel must employ the chosen ballast water management method.

STEPS FOR BALLAST WATER TREATMENT SYSTEM INSTALLATION

Onboard survey and 3D laser scanning

- To determine feasibility, impact and conflicts associated with installing various solutions onboard vessels with no disruption to the vessel’s operation.

Modeling and concept design

- Modelling the selected systems into the existing space for optimal solution

System shortlist or selection

- Based on regulations, technological solutions and onboard feasibility.

Detailed engineering

- Precise production package containing drawings that show all foundations, mechanical, electrical, piping and connection drawings as well as comprehensive overview of all the parts needed for installation.

Project supervision

- Project management including review of structural modification and cabling scopes, detailed piping and cabling specifications, piping and cabling layout, piping preparation, structural arrangement scope for foundations or structural reinforcements, detailed job list, prefabrication inspection, site inspections, progress meetings with shipyard andowners’ representatives.

Installation and commissioning

- Aries Green Solutions can provide installation, commissioning and crew training services worldwide

Ballast Water Management Plans

- To combat the problem of invasive species from ballast water, the IMO adopted the International Convention for the Control and Management of Ships’ Ballast Water and Sediments in 2004. On 8 September 2017, the convention entered into force.

- To obtain the International BWM Certificate, a vessel must

- Have a BWM Plan addressing procedures for BW exchange, BW treatment or both.

- If a BWM System is installed, then approved technical documentation for the BW treatment system installation must be available on board.

- A Ballast Water record book is required, and the vessel must employ the chosen ballast water management method.

Service

- Aries Green Solutions can provide ongoing post-installation support and service through its worldwide network.

2. EXHAUST GAS SCRUBBER SYSTEM

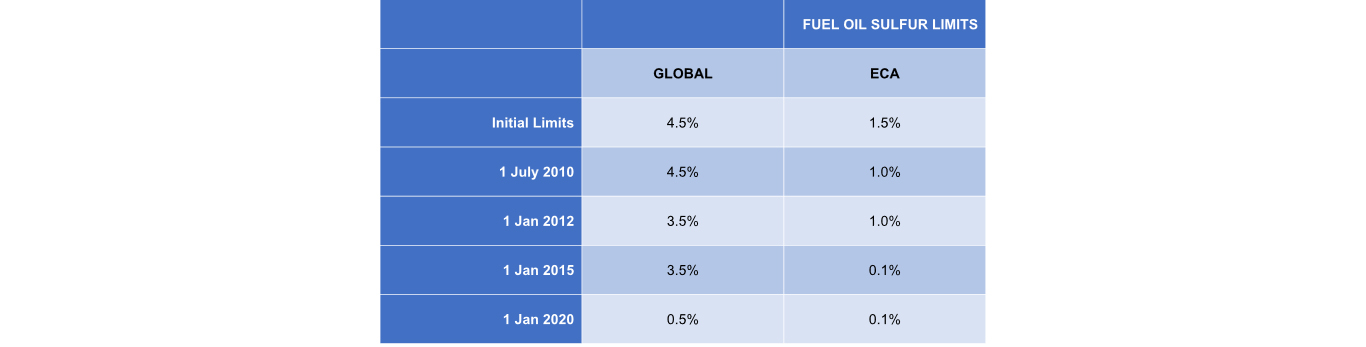

The Marine Environment Protection Committee (MEPC) of IMO adopted the 1997 Protocol to the MARPOL Convention which added Annex VI, Regulations for the Prevention of Air Pollution from Ships. This Annex entered into force on May 19, 2005. In the 70th MEPC session, held in October 2016, member states agreed that a 0.5 percent global sulfur cap on marine fuel would be implemented in 2020 based on the studies that identified the availability of compliant fuel (0.5%).

Aries Green Solutions services include:

Onboard survey and 3D laser scanning

- To determine feasibility, impact and conflicts associated with installing various solutions onboard vessels with no disruption to the vessel’s operation.

Modeling and concept design

- Modelling the selected systems into the existing space for optimal solution

System shortlist or selection

- Based on regulations, technological solutions and onboard assessment

Strength analysis

- Strength analysis based on the vessel specifications

Vibration and stability calculations

- Vibration and stability calculations based on the vessel specifications

Detailed engineering

- Precise production package containing drawings that show all foundations, mechanical, electrical, piping and connection drawings as well as comprehensive overview of all the parts needed for installation

Project supervision

Installation and commissioning

- Aries Green Solutions can provide installing, commissioning and crew training services worldwide

Service

- Aries Green Solutions can provide ongoing post-installation support and service through its worldwide network.

Project management including review of structural modification and cabling scopes, detailed piping and cabling specifications, piping and cabling layout, piping preparation, structural arrangement scope for scrubber foundations or structural reinforcements, detailed job list, prefabrication inspection, site supervision, progress meetings with shipyard and owners’ representatives

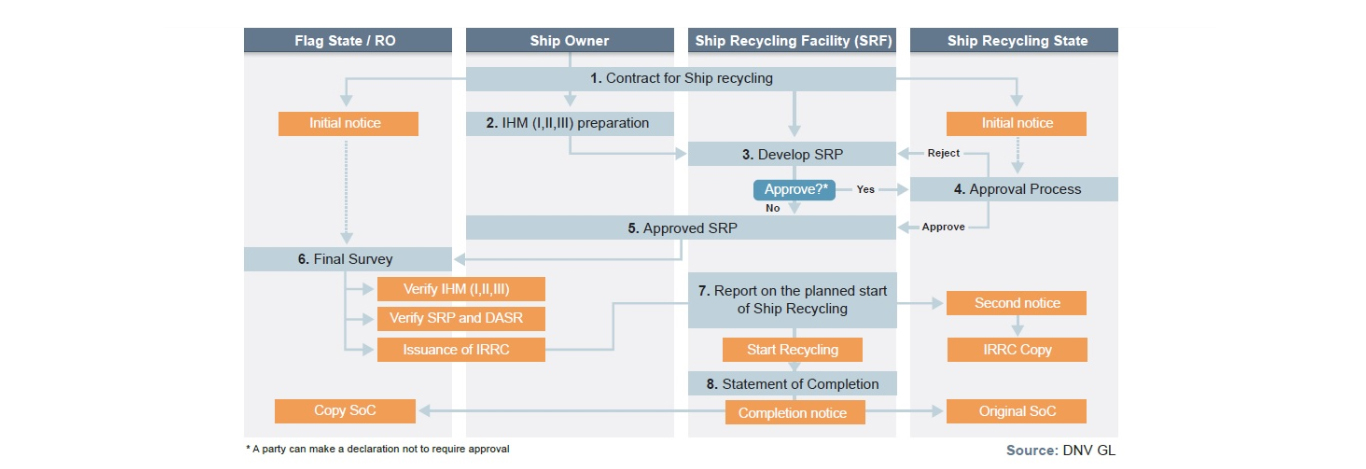

3. SHIP RECYCLING PLANS

The Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, 2009 (the Ship Recycling Convention or the Hong Kong Convention) was adopted in May 2009. After the entry into force of the Convention, the development and maintenance of an Inventory of Hazardous Materials, which identifies the amount and location of hazardous materials onboard a ship, will be required for all ships over 500GT. Furthermore, ships shall only be recycled at ship recycling facilities authorized by the competent authority.

Prior to any recycling of a ship, a ship-specific SRP shall be developed by Aries Green Solutions for the Ship Recycling Facility:

- Based on the information provided by the shipowner (e.g. Inventory of hazardous materials (IHM))

- Including information on how the type and amount of materials will be managed

- The SRP shall be approved by the Competent Authority of the recycling State

Once approved the SRP shall be made available to the ship for its final survey

ARIES GREEN SOLUTIONS SCOPES:

4. THE INVENTORY OF HAZARDOUS MATERIALS

Every year, around 1,000 ships reach the end of their operating life. The European Ship Recycling Regulation (EU SRR) was introduced to ensure proper vessel dismantling methods are used to achieve safe disposal or recycling of all ship components, including hazardous materials.

An Inventory of Hazardous Material (IHM) is a document which provide ship-specific information on the actual hazardous materials present on board in order to protect health and safety of the crew, and to protect health and safety of workers at ship recycling facilities and avoid environmental pollution when the ship is going for recycling.

It is mandatory for all ships larger than 500 tonnes to keep an IHM.

The inventory replaces the Green Passport, adopted in the Hong Kong International Convention in 2009, and is a requirement by the EU Ship Recycling Regulation 2013.

Aries Green Solutions provides the following as part of IHM services:

- Preparation of IHM

- Collection of necessary information and documentation

- Visual/ Sampling Check Plan

- On board verification and collection of samples by HazMat experts

- Collected samples sent for analysis in an accredited laboratory

- IHM report prepared by our trained and certified personnel

- Application for Statement of Compliance (SOC)

- Submission of reports to Class Society and request for SOC

- Verification survey carried out onboard by Class

- Basic result of survey and SOC issued by Class

5. DEMOLITION VOYAGE ADVISORY SERVICES

Aries Green Solutions can provide a one stop solution to vessels heading on their final voyages for demolition from any location across the world.

.The services include:

- Pre Purchase Inspection

- Crew management

- Specific Crew training to ensure proper handling of the vessel on demolition voyages

- Technical Management

- Superintendent attendance at time of take over’s

- Coordinating surveys

- Assistance in Reflagging and class issuance of various certificates

- Navigation and communication equipment set up and surveys as required

- Providing complete solution for Demolition Vessels, Fault Finding, Investigation and Repairs

- Supply of new and reusable spares and implementing cost saving initiatives for owners

6. TECHNICAL DOCUMENTATION FOR GREEN PASSPORT NOTATION REQUIREMENTS

Green Passport refers to ships complying with the requirements of the Hong Kong Convention, 2009 and the requirements, as applicable to ships flying the Flag of non-EU / EU member State, of the Regulation (EU) No 1257/2013 of the European Parliament and of the Council of 20 November 2013 “on ship recycling and amending Regulation (EC) 1013/2006 and Directive 2009/16/EC”.

The documentation prepared by Aries Green Solutions includes:

- Inventory of Hazardous Materials (IHM) Part I

- Diagram of the location of hazardous materials onboard your ship

- Development process and assessment report for the Inventory Part I

- Visual/ Sampling Check Plan and/ or Random Check Plan

- Report of Visual and Sampling Check

- Materials Declaration

- Supplier’s Declaration of Conformity (SDoC)

- Procedure and designated person for the maintenance of the Inventory Part I

7. ISO 14001 & ISO 45001: MARITIME ENVIORNMENT AND HEALTH & SAFETY ADVISORY SERVICES

Aries Green Solutions has provided Maritime Environment and Health & Safety Advisory Services to hundreds of vessels around the world.

ISO 45001

Increased global trade brings new health and safety challenges, which have driven the need for an international OH&S management system standard, to enable global benchmarking and to raise the bar for health and safety in the workplace. Published on 12 March 2018, ISO 45001 aims to help organizations demonstrate their commitment to workplace safety and reinforce their business’ reputation with customers and employees alike.

Organisations certified to OHSAS 18001 will have three years to migrate to the new standard, which introduces a framework that can be used throughout the supply chain to create a health and safety culture that will continually improve your OH&S performance.

.Benefits of ISO 45001

- A clear roadmap to support successful achievement/alignment to the new ISO standard.

- Implementing the changes in the new ISO standard will directly impact your organisation’s health and safety (H&S) risk management effectiveness in the form of a reduction in the potential likelihood and severity of a health and safety related event.

- Increased understanding of the current strengths and weaknesses of your health and safety management and claims defensibility strategies.

- Increased insurer confidence in effectiveness of your controls and associated claims impacts influencing competitive premium rates.

- Demonstrable ability to prove your organisation’s commitment to improving the health and safety environment.

ISO 14001

ISO 14001 is the international specification for an environmental management system (EMS) which helps your organisation identify, prioritise, and manage your environmental risks as part of your normal business practices and quality assurance processes.